TOOL CHANGE

Steam chest change

The extra energy-saving change option, in which the steam chest size and depth adapt to the molded part

Flexibility

- Different steam chest sizes with the most diverse mold concepts can be flexibly used on one machine

- Existing molds can be used without changes

Energy saving potential

- Low energy consumption due to adaptation of the steam chest to the molded part

- With optimized steam chest adapter, monoblocks and additively manufactured molds

Reduced downtime

- Existing molds can be completely pre-equipped on mold changing devices in a user-friendly manner

- Minimal downtime during product changeover thanks to decentralized setup of the steam chest

Quick mold change

The fastest changeover variant because the entire steam chest is not replaced

Reduced downtime

- Existing molds can be completely pre-equipped on mold changing devices in a user-friendly manner

- Minimal downtime during product changeover due to decentralized mold setup

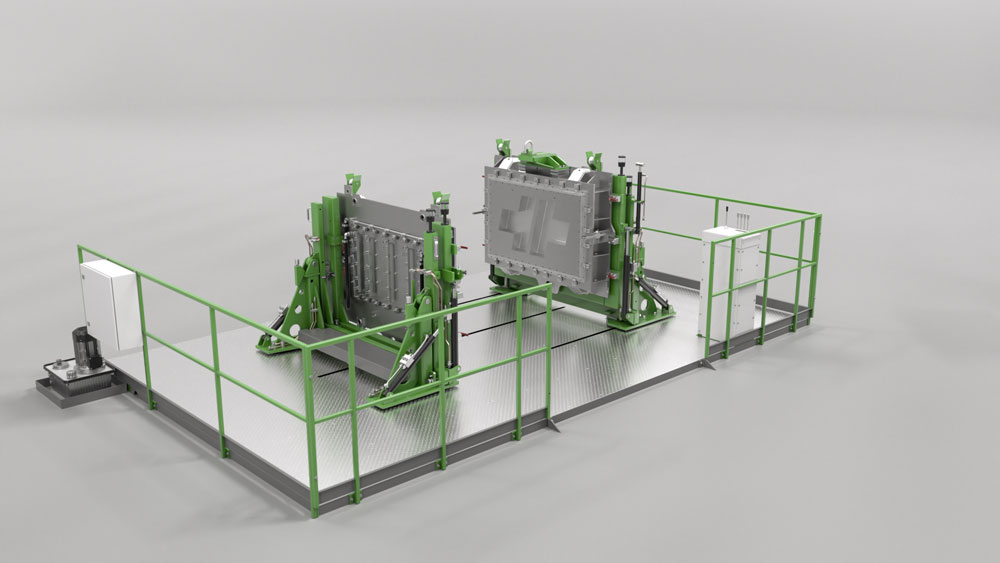

Mold changing device

- Steam chest or mold can be set up outside the production line

- Ergonomic workspace

- Very high accuracy when closing and opening the steam chest/mold

- Hydraulic assistance in opening and closing over approx. 500 mm

- Core side hydraulically swiveling

- Core and hood side hydraulically height adjustable

- In two versions:

- Variant 1: Horizontal traverse movement

- Variant 2: Horizontal and vertical traversing movement and 90° swiveling