Blumberg

Südschwarzwald

Deutschland

Herzlich

Willkommen

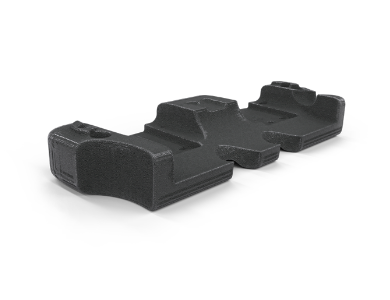

Wir sind Ihre Experten für maßgeschneiderte Maschinen zur Verarbeitung von Partikelschäumen und faserverstärkten Thermoplasten. Weltweit. Und immer mit umfassenden Antworten auf Ihre Anforderungen.

Das bedeutet: Wir planen. Wir entwickeln. Wir konstruieren. Wir bauen.

Das Ergebnis: Ihre individuelle Lösung. Das kann eine Standardmaschine sein. Oder eine Sondermaschine. Bei Bedarf mit Automatisierung, nach höchstem Standard. Und mit Anwendungen im Bereich Industrie 4.0. Exakt das, was Sie brauchen. Was wir garantieren können: 1 A Expertise bei der Verarbeitung von Partikelschäumen und faserverstärkten Thermoplasten. Und Qualität made in Germany – von der Entwicklung und Konstruktion über die Fertigung und Montage. Mit zuverlässiger Inbetriebnahme und Service überall auf der Welt.

Mit der Erfahrung aus 3 Generationen und vielen langjährigen Mitarbeitern. Auftraggebern aus den Bereichen Automobil, Luft- und Raumfahrt, Schiene, Sport und Outdoor, Heizung und Lüftung, Bauen und Wohnen. Und mit vielen langjährigen Kundenbeziehungen in wertschätzender und intensiver Zusammenarbeit, die unsere Lösungen immer den entscheidenden Schritt besser machen.

Wo sind Sie? Welches Vorhaben wollen wir gemeinsam angehen?

Herzlich willkommen.

Mitarbeiter

%

Technischer Support

& Customer Care

Jahre

Erfahrung

BRANCHEN UNSERER KUNDEN

Termine